FAQ

Have Questions?

Below you’ll find answers to the most common questions you may have about electrical installations and automation systems. If you still can’t find the answer you’re looking for, just Contact Us!

When it comes to electrical installation, “Safe and Secure” means ensuring that the electrical system is configured correctly to prevent accidents, fires or electrocution, while providing reliable power. Here are some key aspects to ensure that electrical installations are safe and secure:

1. Proper Wiring and Components

Correct Wiring: Use right type and size of wires for the intended load. Overloading can lead to overheating or short circuits.

Quality Components: Ensure that protection devices (e.g., breakers – MCB, RCCD/ RCCB, fuse switch disconectors, etc.), control devices (e.g., key switches, push butons, etc.), are of high quality and approved by regulatory authorities (e.g., EN or IEC standards).

2. Circuit Protection

Circuit Breakers/Fuses: Install circuit breakers or fuses to protect wiring and prevent overloads or short circuits. They automatically disconnect power if there’s a fault.

Ground Fault Circuit Breakers (RCCDs, RCBOs): Install RCCDs for specific circuits (like sockets, etc.) to protect against electric shocks.

3. Grounding

Proper grounding of electrical systems prevents electrical shock and helps protect against surges and lightning strikes.

Ground all appliances, outlets, and other electrical components to reduce the risk of electrical hazards.

4. Compliance with Electrical Codes

Follow local electrical codes (such as the I7 normative, SR EN standards in Romania, or IEC, EN in Europe) when designing and installing an electrical system. These codes ensure that installations are safe for both short-term and long-term use.

Hiring a licensed electrician is crucial to meet all legal and safety standards.

5. Inspection and Maintenance

Regular Inspections: Have a professional electrician inspect the installation to catch potential issues like frayed wires, overloaded circuits, or outdated components.

Upkeep: Check for any exposed wires, faulty outlets, or faulty equipment. Don’t ignore any signs of electrical issues like buzzing sounds or tripped circuit breakers.

6. Fire Safety

Proper Insulation: Use insulated wires to prevent short circuits and fires.

No Overloading: Don’t overload circuits or plug too many devices into one outlet. This can cause excessive heat and lead to a fire.

7. Surge Protection

Install surge protectors to protect sensitive electronics devices and appliances from power surges, which can occur due to lightning strikes or grid problems.

8. Clear Marking

Clearly label circuit breakers and fuse panels to ensure they can be easily identified in an emergency.

Make sure all electrical panels are accessible and not obstructed.

9. Safety Signage

Use warning signs around electrical panels or areas with high voltage to inform people of potential hazards.

In short, a safe and secure electrical installation involves using quality materials, following codes, ensuring proper protection and grounding, and conducting regular checks and maintenance to prevent electrical hazards.

In summary, 24/7 support for your electrical systems ensures that you always have access to help when you need it most, providing a quick response to emergencies, reducing downtime, and maintaining safety. It is especially critical for businesses or environments where electrical systems are essential to daily operations.

Having 24/7 support can significantly enhance safety, reliability, and last but not least your peace of mind. It ensures that if any issues arise with your electrical system, you can quickly address them, minimizing downtime and reducing the risks of accidents. Here’s why 24/7 support is important and what we can offer:

1. Emergency Assistance

Immediate Response: Electrical issues can occur at any time, and problems like power outages, short circuits, or electrical fires require immediate attention. With 24/7 support, you have access to trained professionals who can resolve these issues quickly, minimizing the potential for damage or hazards.

After-hours Support: Many electrical problems happen after business hours or during weekends.

Preventing Long-Term Damage: Quick intervention can often prevent small problems from turning into major, expensive issues that could compromise safety and cause further damage to appliances or wiring.

2. Preventing Downtime

Continuous Operations: For businesses, electrical problems can cause operational downtime. It is important that your business continues to run smoothly and without long interruptions.

Monitoring: For critical systems we can ensure remote monitoring, meaning technicians can detect issues before they become major problems, offering proactive solutions.

4. Expert Guidance

Advice and Troubleshooting: We can offer guidance and help you troubleshoot minor issues without the need for a physical visit. This can be useful for things like resetting circuit breakers or identifying simple problems.

Qualified Engineers: Trained, licensed professionals can be dispatched to ensure that all electrical work is done safely and in compliance with safety standards.

5. Maintenance Support

Scheduled Checks: With ongoing 24/7 support, you can schedule routine inspections and maintenance, reducing the chances of unplanned emergencies.

Remote Monitoring: In some cases, remote monitoring services may detect potential failures (like overloaded circuits or faulty systems) before they become critical, allowing for immediate repair or replace.

24/7 Electrical support can be accessed through service contract.

A fair price for our services includes:

– Transparent, upfront quotes

– Competitive pricing based on market standards

– Reasonable emergency charges

– A balance of quality and cost

– Free estimates or consultations

– Discounts for regular maintenance or package deals

– Licensed professionals providing high-quality work

Ultimately, the fair price reflects a balance of good value, quality service, and transparency. It ensures that customers are not overcharged while receiving reliable, professional work.

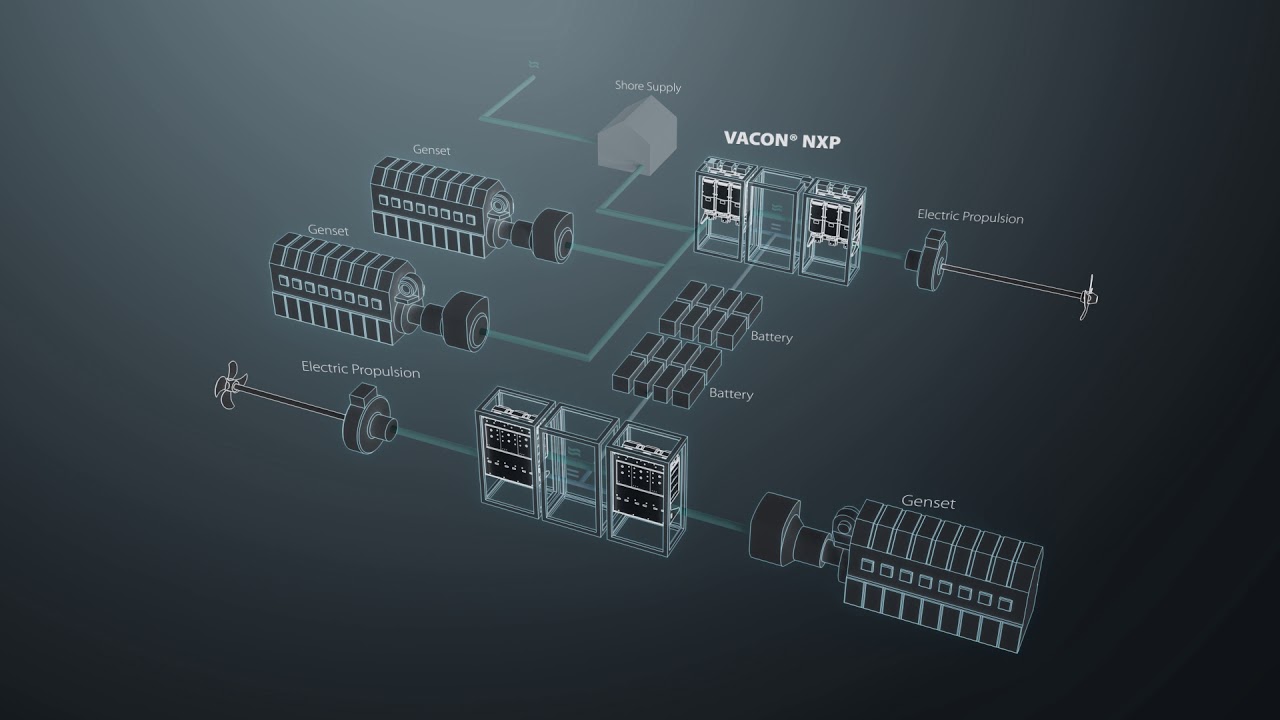

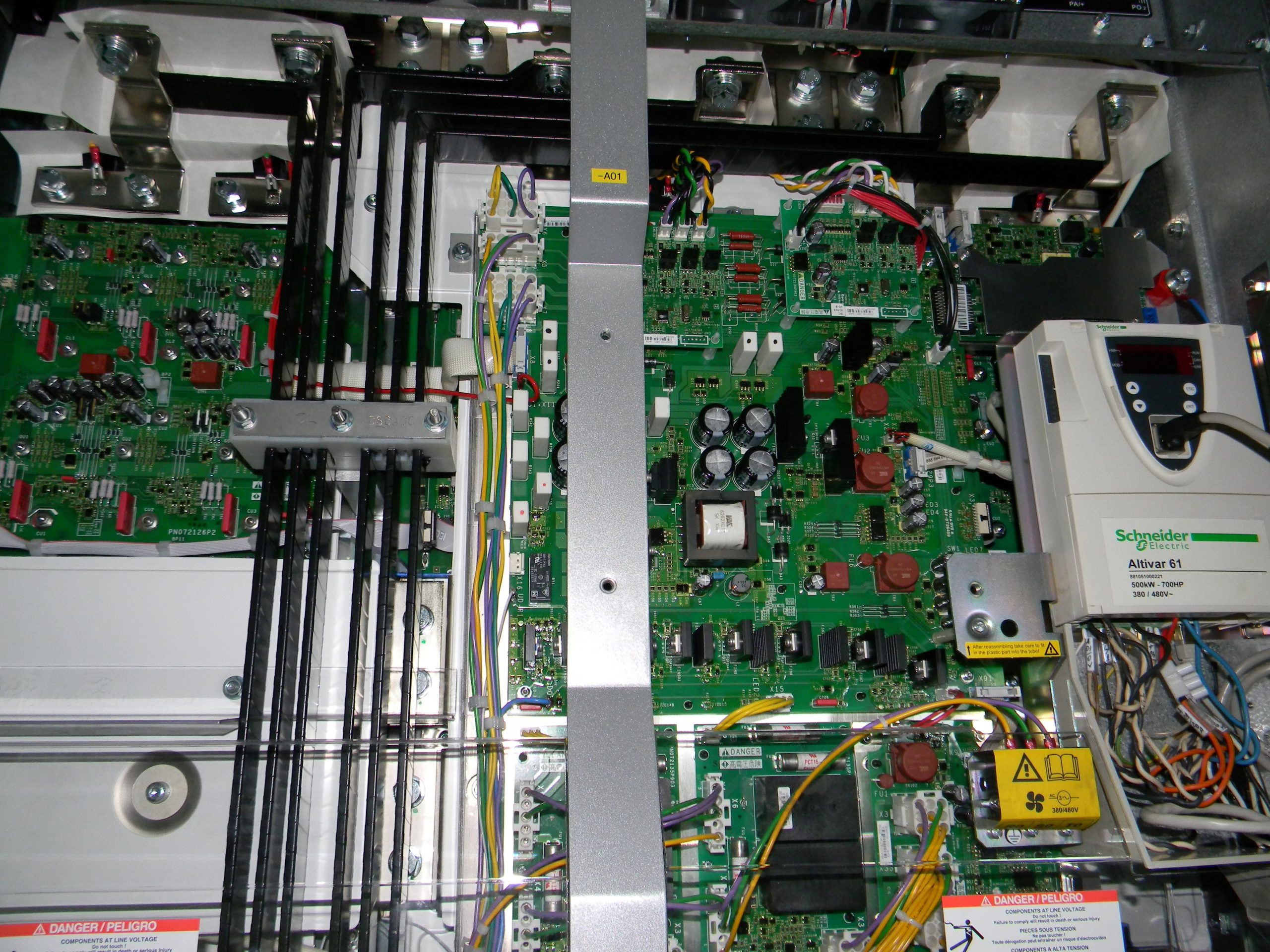

It involves the use of various technologies such as sensors, controllers, and programmable logic controllers (PLCs) to automate the operation of electrical systems. Electrical automation engineering plays a crucial role in modern industrial processes, improving efficiency, productivity, and safety.

Today, electrical devices have become more sophisticated and can be programmed like drives and switch gears also. Automation is covering not only instrumentation but also electrical devices like a MCBs, MCCBs, contactors, protection relays, servo motors, motors, AC DC drives control which communicates and is controlled by the PLC and SCADA.

Artificial Intelligence is redefining the boundaries of what’s possible, turning complex challenges into manageable tasks. From enhancing system efficiencies to pioneering innovative solutions, AI is the new powerhouse in electrical engineering.

Retrofitting means upgrading or converting existing equipment, control panels and automation systems to:

- Meet current performance and safety standards

- Adapt to new processes or operational requirements

- Extend the life of older or obsolete equipment

- ✅ Cost-Effective: Much cheaper than purchasing new equipment

- ♻️ Sustainable: Supports the circular economy by reusing functional parts

- ⚡ Energy Efficient: Incorporates newer, low-consumption components

- 🧠 Smarter Control: Enhanced performance through updated software

- 🔐 Safe & Reliable: Improves system safety and operational reliability

EMC (Electromagnetic Compatibility) means nothing more than “an electronic or electrical product shall work as intended in its environment. The electronic or electrical product shall not generate electromagnetic disturbances, which may influence other products”. In other words, EMC deals with problems of noise emission as well as noise immunity of electronic and electrical products and systems. Electromagnetic disturbances occur as conducted interference as well as radiated emissions and immunity problems.

Electromagnetic interference (or EMI, also called radio frequency interference or RFI) is a disturbance that affects an electrical circuit due to either electromagnetic conduction or electromagnetic radiation emitted from an external source. The disturbance may interrupt, obstruct, or otherwise degrade or limit the effective performance of the circuit. The source may be any object, artificial or natural, that carries rapidly changing electrical currents, such as an electrical circuit or the Sun.

Have you ever wondered why the interference that you receive on the radio communications bands can sometimes disrupt the intended signals? Interference probability is based on the potential power transfer densities involved due to the proximity of equipment and antenna systems; the various transfer mechanisms, and equipment performance.

The electromagnetic transfer mechanisms may vary depending on modes of operation, propagation conditions, and other variables. The propagation paths that exist for signal transfer from the transmitters to a receiver within the RF environment of a radio communications band can be numerous.

Antenna-to-antenna coupling parameters may vary depending on antenna gain, directivity, beam width, side lobes, polarization, separation, propagation conditions of the path (path loss), etc. The receiver characteristics which influence performance include noise, dynamic range, sensitivity, selectivity (RF, IF), desensitization, adjacent signal susceptibility, intermodulation, cross modulation and spurious response susceptibility.

The terms EMI and RFI are often used interchangeably. EMI is actually any frequency of electrical noise, whereas RFI is a specific subset of electrical noise on the EMI spectrum. There are two types of EMI.

Conducted EMI is unwanted high frequencies that ride on the AC wave form.

Radiated EMI is similar to an unwanted radio broadcast being emitted from the power lines. There are many pieces of equipment that can generate EMI, variable frequency drives included. In the case of variable frequency drives, the electrical noise produced is primarily contained in the switching edges of the PWM controller. As the technology of drives evolves, switching frequencies increase. These increases also increase the effective edge frequencies produced, thereby increasing the amount of electrical noise.

If you are occasionally experiencing interference with your telephone system, flickering computer monitors, reliability issues with computer networks, instrumentation errors, or misbehaving electronics you are most likely experiencing RFI in your electrical environment. RFI can wreak havoc with your electronics, computers and telephones, making your workplace difficult to work in. Since most machines have control electronic circuits, they may become difficult to control or unreliable. RFI The disturbance may interrupt, obstruct, degrade or limit the effective performance of the circuit.

Depending on your application, there are many ways to reduce the effects of RFI. For conducted RFI, you can choose from a large range of RFI filters, chokes & pulse transformers. For radiated RFI, you can choose from a large range of shielding products.

RFI filters are available as feed-through components, or as PCB filters, IEC inlet filters and power entry modules, 3-phase filters, 3-phase and neutral line filters, output filters, EMC/EMI chokes and pulse transformers.

Request a Quote Today

Reach Us

Location :

Bistrita, Amurgului 17

420078, Bistrita-Nasaud

Romania

Email :

Phone :

office: +40 363 408 233

mobile: +40 720 530 045